Silicone rubber molding is a manufacturing process used to create various silicone rubber products.

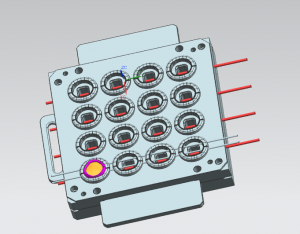

Here is a typical process flow for silicone rubber molding: Creating a mold: The first step is to create a mold, which is a negative replica of the desired final product. The mold can be made from various materials such as metal, plastic, or silicone rubber. The mold design should include all the necessary details and features of the final product.

Preparing the silicone material: Silicone rubber is a two-component material that consists of a base compound and a curing agent. These components are mixed together in specific proportions to create a homogeneous mixture.

Applying release agent: To prevent the silicone rubber from sticking to the mold, a release agent is applied to the mold surface. This can be a spray, liquid, or paste, which forms a thin barrier between the mold and the silicone material.

Pouring or injecting the silicone: The mixed silicone material is poured or injected into the mold cavity. The mold is then closed or secured, ensuring no leakage occurs during the molding process.

Curing: Silicone rubber is a cured material, meaning it undergoes a chemical reaction to transform from a liquid or viscous state to a solid state. The curing process can be accelerated by applying heat, using a vulcanization oven, or by letting it cure at room temperature, depending on the specific type of silicone being used. Demolding the product: Once the silicone has fully cured and solidified, the mold can be opened or separated to remove the molded product. The release agent helps in ease of demolding and prevents any damage to the final product.

Post-processing: After the silicone rubber product is demolded, any excess material, flash, or imperfections can be trimmed or removed. Some additional finishing touches may be required depending on the specific requirements of the product. It's important to note that this is a general overview of the silicone rubber molding process.

Depending on the complexity of the product, specific variations or additional steps may be involved

Post time: Aug-01-2023