Silicone Keypad Design Rules and Recommendations

Here at JWT Rubber we have vast experience in the custom silicone keypad industry. With this experience we have established some rules and recommendations for the design of silicone rubber keypads.

Below are some of these rules and recommendations:

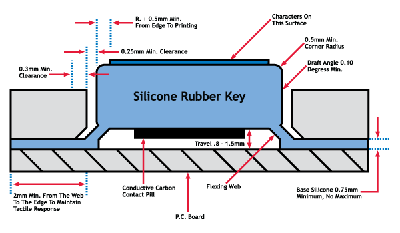

1, The minimum radius capable of being used is 0.010”.

2, It is not recommended to use anything smaller than 0.020” in deep pockets or cavities.

3, Keys that are taller than 0.200” are recommended to have a minimum draft of 1°.

4, Keys that are taller than 0.500” are recommended to have a minimum draft of 2°.

5, The minimum thickness of a keypad mat should be no less than 0.040” thick

6, Making a keypads mat too thin can have a negative effect on the force profile you are seeking.

7, The maximum thickness of a keypad mat should be no more than 0.150” thick.

8, Air channel geometry is recommended to be 0.080” – 0.125” wide by 0.010” – 0.013” deep.

Holes or openings within the silicone part require tear plugs which are removed either by hand or tweezers. This means that the smaller the opening the more difficult it will be to remove the plug. Also the smaller the plug the more chance for residual flash to be left on the part.

The clearance between a bezel to a key should be no less than 0.012”.

Silicone keypads have the capability of being backlit. This is done with the use of LED lighting via a printed circuit board. Typically an LED insert or clear window is insert molded into the keypad to show the light. LED light pipes, windows and displays have a few design recommendations as well.

Let’s checking some drawings for better understanding.

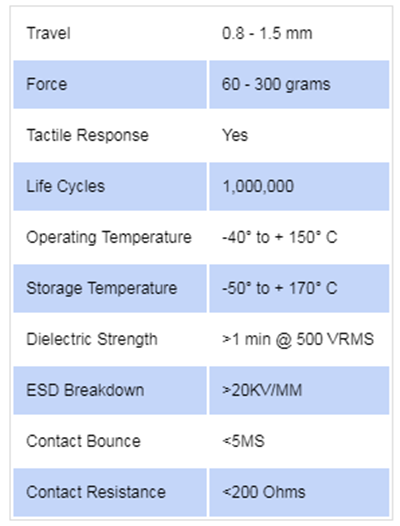

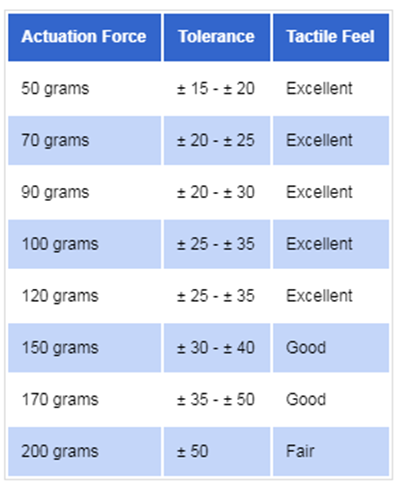

Button Travel (mm)

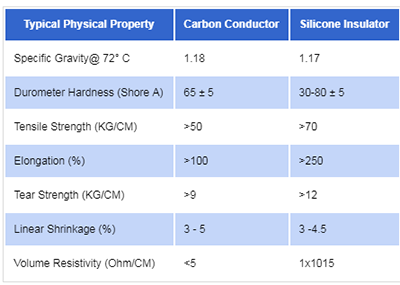

Physical Properties of Silicone Rubber

RUBBER KEYPAD DESIGN GUIDE

Post time: Aug-05-2020