How Does A Silicone Keypad Work?

First, let’s figure out what is Silicone Keypad?

Silicone rubber keypads (also known as Elastomeric Keypads) are used extensively in both consumer and industrial electronic products as a low cost and reliable switching solution.

In its most basic form, a silicone keypad is basically a “mask” that is placed over a series of switches in order to provide a more comfortable and tactile surface for users. There are a number of varieties of silicon keypads.JWT Rubber can produce keypads with far more advanced features than those listed below. But it is important any designer understands the general process by which silicon keypads convert user input into signals that operate electronics and machinery.

Silicone Keypad Production

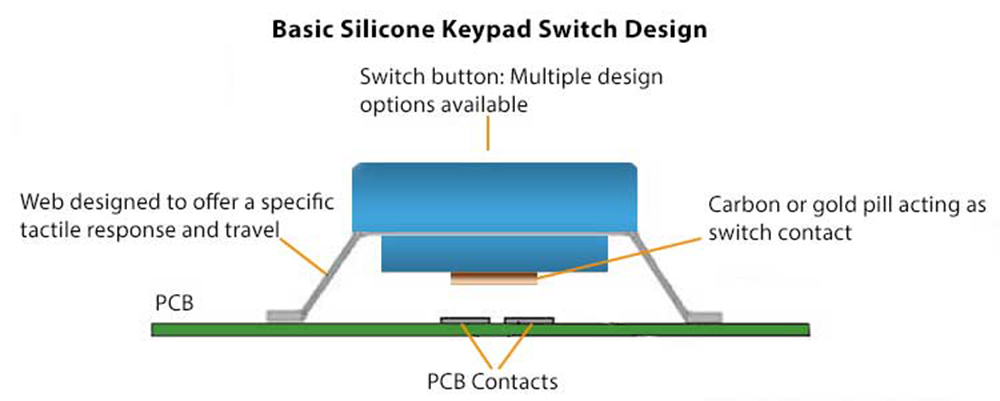

Silicone keypads are made with a process called compression molding. The process basically uses a combination of pressure and temperature to create pliable (yet durable) surfaces around central electronic contacts. Silicone keypads are designed to produce a uniform tactile response across the entire surface. They are designed to be electronically neutral so interference from the material is not a factor in the use of the device.

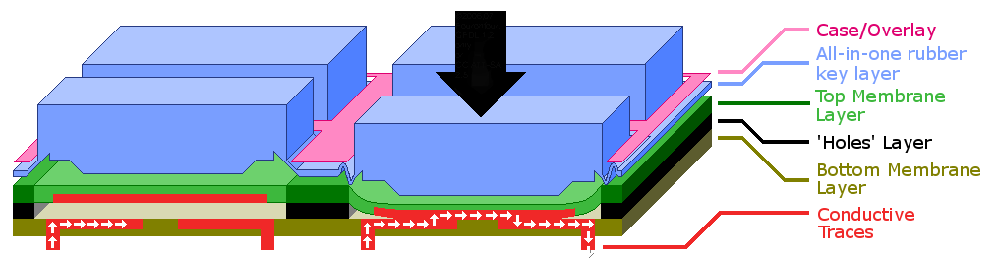

One important consideration of silicon keypads is the ability to make the entire keypad a single piece of silicone webbing, rather than having individual keys produced separately. For a device such as a remote control, this allows for greater ease of production (and lower costs) since the keypad can be inserted as a single piece underneath a plastic holding device. This also increases the resistance of a device to fluids and environmental damage. For example, if you spill a liquid on a silicon keypad that is made of one solid piece of silicone, the fluid can be wiped off without infiltrating the device and causing damage to the internal components.

Silicone Keypad Inner Workings

Underneath each key on a silicone keypad is a relatively simple series of electronic contacts that help deliver electronic impulses when keys are depressed.

When you press a key on the keypad, it depresses that section of the silicone web. When pressed enough that the carbon/gold pill on the key touches the PCB contact underneath that key to complete a circuit, the effect is completed. These switch contacts are extremely simple, which means they are cost-effective and VERY durable. Unlike many other input devices (looking at you, mechanical keyboards) the effective life of a silicone keypad is effectively infinite.

Customizing Silicone Keypads

The versatile nature of silicone allows for a huge degree of customization of the keypad itself. The amount of pressure that it takes to press a key can be changed by modifying the “hardness” of the silicone. This can mean the requiring a greater tactile force to depress the switch (although webbing design is still the greatest contributor to actuation force). The shape of the key also plays a role in its overall tactile feel. This aspect of customization is called “snap ratio”, and it is a balance between the ability to make keys feel independent/tactile, and the desire for designers to produce a keypad that will have a higher life span. With enough of a snap ration, keys will actually feel as though they are “clicking”, which is satisfying for the user, and gives them feedback that their input was understood by the device.

Post time: Oct-05-2020