Our professional engineering team, which can assess the technical feasibility of your ideas and design, also will give advice on materials and design to reduce your costs

Features of Customized Waterproof Molded Rubber Grommet

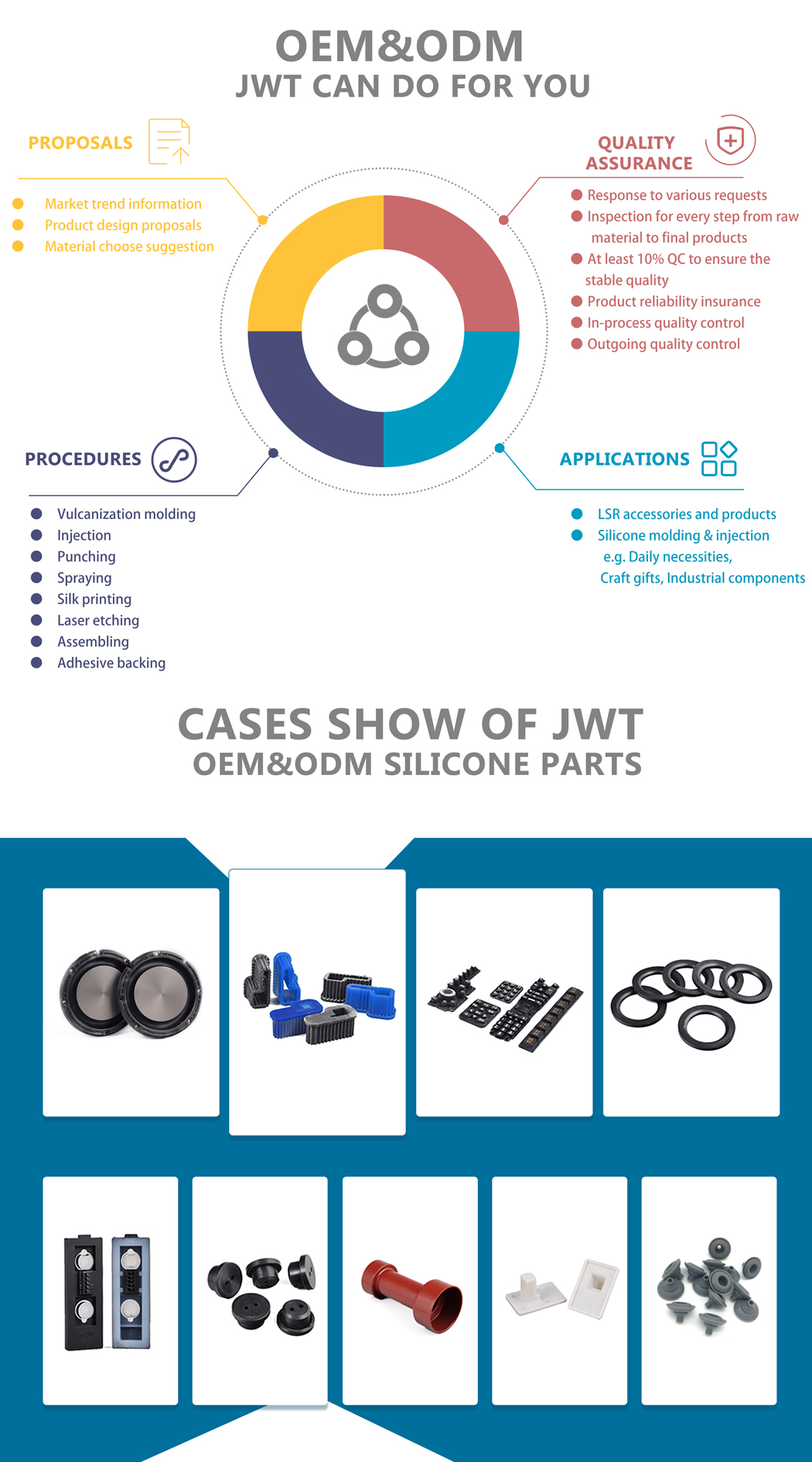

Focus on OEM/ODM service ,customizing project with your samples or drawings.

Offer customized service for branded corporation since 2007.

Offering products meet with Rohls, Reach, FDA ,LFGB compliant.

Silicone part includes pure silicone solid parts, liquid silicone part, LSR,HTV silicone,and so on.

Provide the best material according to product application and performance requirement.

We can provide you with one-stop logistics and customs clearance service.